新闻中心

齿轮齿条在设计过程中的注意事项

来源:http://www.jngongrun.com/ 日期:2023-07-13 发布人:

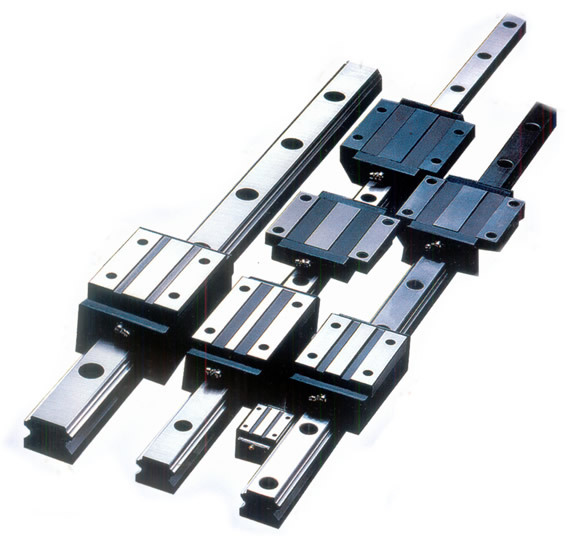

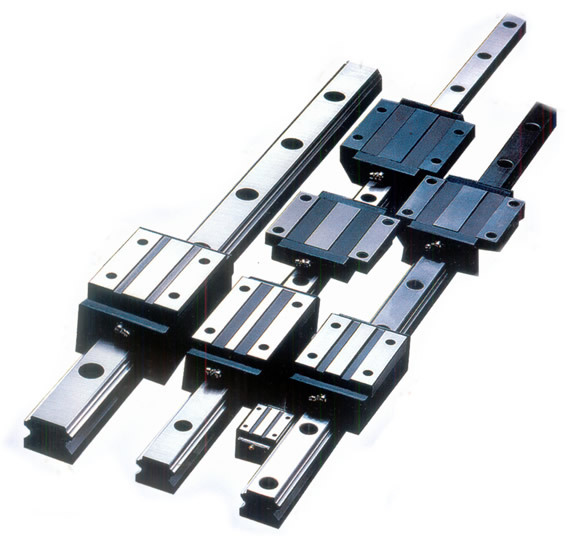

齿轮齿条在传动中经常需要根据实际情况去设计,在自动化行业,很多齿轮齿条都是配合行星减速机去使用的,今天导轨丝杠厂家给大家介绍一下,齿轮齿条设计的注意事项有哪些?

In transmission, gears and racks often need to be designed according to actual situations. In the automation industry, many gears and racks are used in conjunction with planetary reducers. Today, the guide rail screw manufacturer will introduce to you the precautions for gear and rack design?

1、齿条的宽度

1. The width of the rack

在实际应用中,齿轮的宽度要大于齿条的宽度,一般情况下模2斜齿圆柱齿轮宽度为26mm,模3齿轮为31mm。

In practical applications, the width of the gear should be greater than the width of the rack. Generally, the width of the helical cylindrical gear in module 2 is 26mm, and that of the gear in module 3 is 31mm.

2、齿轮内孔公差

2. Tolerance of gear inner hole

当齿轮与轴式减速机热装时,一般齿轮内孔公差取与减速机轴过渡配合,具体公差要参考减速机轴公差。

When gears and shaft reducers are hot assembled, the tolerance of the gear inner hole is generally taken as a transitional fit with the reducer shaft, and the specific tolerance should refer to the reducer shaft tolerance.

3、法兰盘齿轮安装凸台公差

3. Flange gear installation boss tolerance

法兰盘齿轮凸台公差一般取与法兰盘减速机安装孔间隙配合,这样才便于调整总的输出跳动。

The tolerance of the flange gear boss is generally taken to match the clearance of the installation hole of the flange reducer, so as to facilitate the adjustment of the overall output runout.

4、齿轮长度

4. Gear length

原则上齿轮总长度(含轮毂)越短越好,齿轮越短减速机输出轴所受倾覆力矩越小,在齿轮设计过程中要严格参考减速机倾覆力矩参数。

In principle, the shorter the total length of the gear (including the hub), the better. The shorter the gear, the smaller the overturning torque on the output shaft of the gearbox. In the gear design process, strict reference should be made to the overturning torque parameters of the gearbox.

5、齿轮长度与减速机轴长的关系

5. The relationship between gear length and reducer shaft length

斜齿圆柱齿轮由于存在轴向力,当采取齿轮热装和花键连接时,齿轮设计过程中,齿轮与减速机轴的配合长度设计,齿轮长度要略大于减速机轴长度,这样齿轮端面盖板才能发挥作用。

Due to the existence of axial force in helical cylindrical gears, when gear hot fitting and spline connection are used, the matching length between the gear and the reducer shaft is designed during the gear design process. The gear length should be slightly larger than the reducer shaft length, so that the gear end face cover plate can play a role.

6、外置盖板与内嵌盖板的应用

6. Application of External Cover Plate and Embedded Cover Plate

花键齿轮统一采取内嵌盖板,因为花键连接,本身减速机的轴已经缩短。如果采取热装,尽可能选取外置盖板,这样可以缩短力臂,如果齿条安装面空间有限再考虑内置盖板。

The spline gear adopts an embedded cover plate, as the shaft of the reducer itself has been shortened due to the spline connection. If hot installation is adopted, an external cover plate should be selected as much as possible to shorten the force arm. If the space for the rack installation surface is limited, an internal cover plate should be considered.

7、齿轮齿数

7. Number of gear teeth

在齿轮设计过程中,为了防止齿轮根切,一定要记住标准齿轮的少齿数,一般不采取少于少齿数的齿轮,如果一定要用少于少齿数的齿轮,需要合理计算变位系数。

In the process of gear design, in order to prevent gear undercutting, it is necessary to remember the minimum number of teeth of the standard gear. Generally, gears with less than a minimum number of teeth are not used. If it is necessary to use gears with less than a minimum number of teeth, it is necessary to calculate the modification coefficient reasonably.

齿轮齿条在设计过程中的注意事项就讲解到这里了,希望能够给您好的帮助,更多事项就来我们网站http://www.jngongrun.com咨询!

That's all we need to pay attention to during the design process of gears and racks. We hope it can be helpful to you. For more details, please visit our website http://www.jngongrun.com consulting service

- 上一篇:简述直线光轴的质量和其他问题

- 下一篇:导轨丝杠发展趋势有几点?

导轨丝杠:从设计结构...<>

导轨丝杠:从设计结构...<> 大型丝杠的性能设计介...<>

大型丝杠的性能设计介...<> 梯形丝杠和滚珠丝杠的...<>

梯形丝杠和滚珠丝杠的...<> 滚珠丝杆目前的行业的...<>

滚珠丝杆目前的行业的...<> 滚珠丝杠螺母油封更换...<>

滚珠丝杠螺母油封更换...<>

相关: