导轨丝杠的工作机制、性能优势是什么?

来源:http://www.jngongrun.com/ 日期:2025-03-20 发布人:

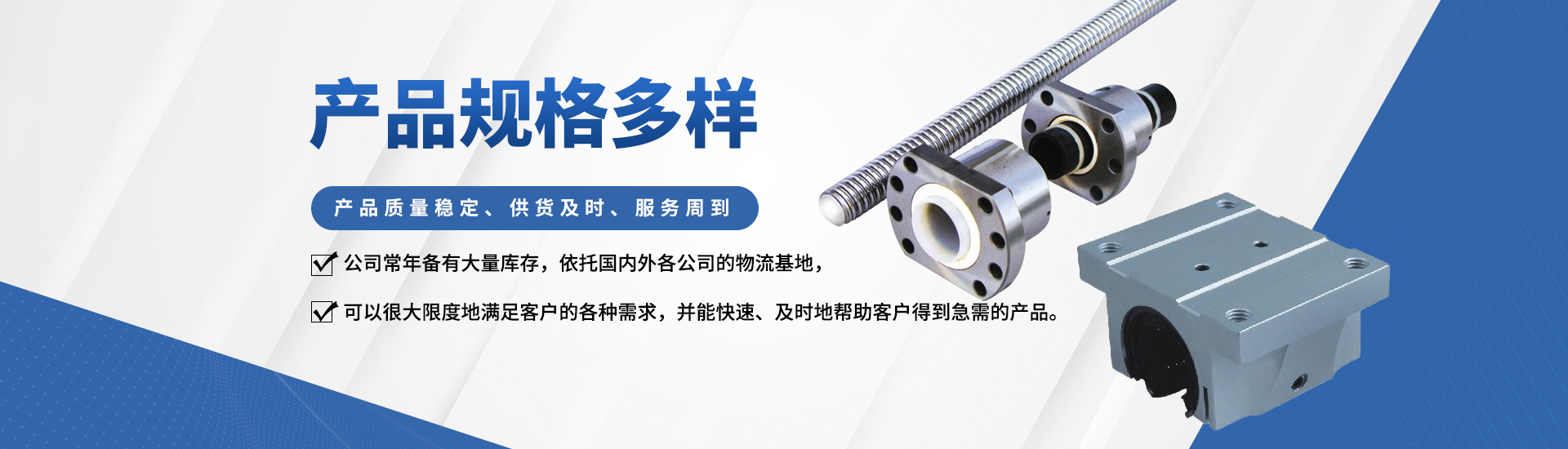

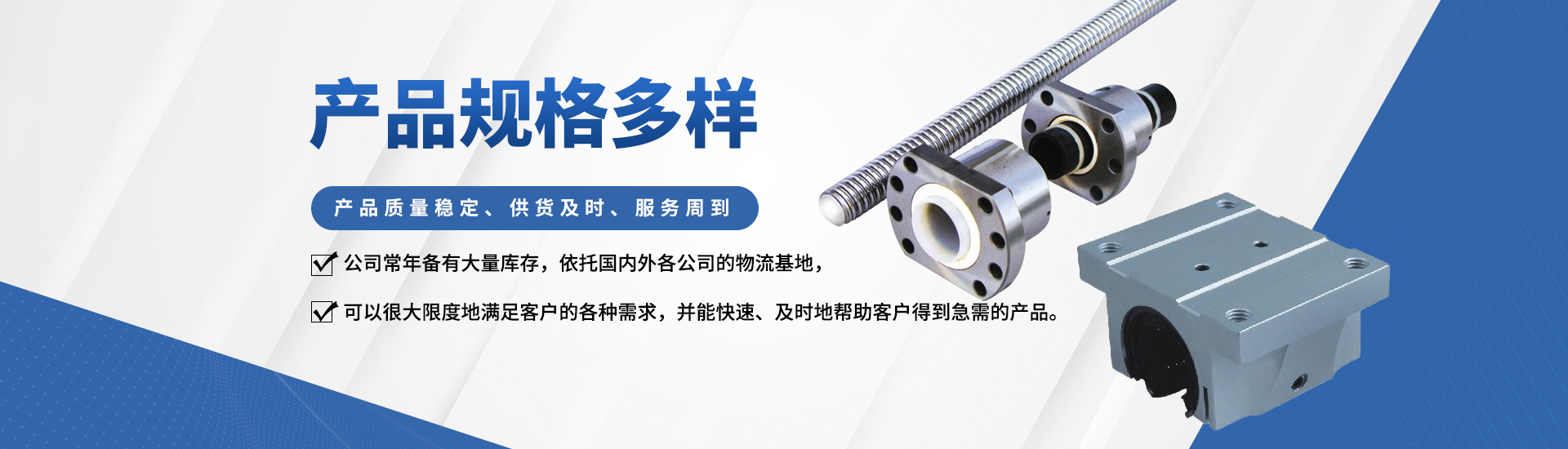

在现代工业制造的精密体系中,导轨丝杠宛如隐藏在设备内部的精密 “工匠”,虽不引人注目,却对设备的精准运行与生产起着关重要的作用。从自动化机床到高端 3D 打印机,从医疗器械到航空航天设备,导轨丝杠无处不在,为各类工业应用提供稳定、精确的线性运动。

In the precision system of modern industrial manufacturing, the guide screw is like a precision "craftsman" hidden inside the equipment. Although not eye-catching, it plays a crucial role in the precise operation and efficient production of the equipment. From automated machine tools to high-end 3D printers, from medical equipment to aerospace equipment, guide screws are everywhere, providing stable and precise linear motion for various industrial applications.

工作原理

Working principle

当电机驱动丝杠旋转时,螺母会沿着丝杠的轴向做直线运动。在这个过程中,导轨起到导向和支撑的作用,确保螺母及与之相连的运动部件能够沿着预定的直线轨迹平稳移动。对于滚珠丝杠,电机带动丝杠旋转,滚珠在丝杠和螺母的滚道内滚动,同时推动螺母移动。滚珠的循环方式有内循环和外循环两种。内循环是指滚珠在螺母内部的循环通道内循环,其结构紧凑,噪音低;外循环则是滚珠通过外部的循环装置进行循环,适用于负载较大的场合。导轨丝杠的这种将旋转运动精确转化为直线运动的工作原理,为工业设备的各种精密操作提供了基础。

When the motor drives the screw to rotate, the nut will move in a straight line along the axial direction of the screw. In this process, the guide rail plays a guiding and supporting role, ensuring that the nut and its connected moving parts can move smoothly along the predetermined linear trajectory. For ball screws, the motor drives the screw to rotate, and the ball rolls in the raceway of the screw and nut, while pushing the nut to move. There are two ways for ball bearings to circulate: internal circulation and external circulation. Internal circulation refers to the circulation of the ball in the internal circulation channel of the nut, with a compact structure and low noise; External circulation refers to the circulation of balls through an external circulation device, which is suitable for situations with high loads. The working principle of the guide screw, which accurately converts rotational motion into linear motion, provides a foundation for various precision operations of industrial equipment.

导轨丝杠的性能优势

Performance advantages of guide screw

高精度定位

High precision positioning

导轨丝杠能够实现极高的定位精度,这是其在众多工业领域得以广泛应用的关键原因之一。滚珠丝杠的精度可以达到微米级,甚在一些高端应用中能够实现亚微米级的定位精度。通过精密的加工工艺和严格的质量控制,丝杠的螺纹螺距误差、导轨的直线度误差等都被控制在极小的范围内。例如,在半导体制造设备中,芯片的光刻、蚀刻等工艺需要极高的定位精度,导轨丝杠能够确保设备的工作台在微米甚纳米级别的精度下移动,从而保证芯片制造的高精度和良品率。

The guide screw can achieve extremely high positioning accuracy, which is one of the key reasons for its wide application in many industrial fields. The accuracy of ball screws can reach micrometer level, and even achieve sub micrometer level positioning accuracy in some high-end applications. Through precise machining techniques and strict quality control, the thread pitch error of the screw and the straightness error of the guide rail are controlled within a very small range. For example, in semiconductor manufacturing equipment, processes such as photolithography and etching of chips require extremely high positioning accuracy. The guide screw can ensure that the equipment's worktable moves with precision at the micrometer or even nanometer level, thereby ensuring high precision and yield in chip manufacturing.

高负载能力

High load capacity

导轨丝杠具有出色的负载能力,能够承受较大的轴向力和径向力。导轨的设计和材料选择使其能够稳定支撑运动部件的重量,同时抵抗设备运行过程中产生的各种外力。对于丝杠而言,其直径、螺纹牙型以及材料的强度等因素决定了它的负载能力。在大型机床中,导轨丝杠需要承受重达数吨的工作台和工件的重量,同时还要保证在高速切削过程中,能够稳定地驱动工作台进行精确的进给运动,这就对导轨丝杠的负载能力提出了极高的要求。

The guide screw has excellent load capacity and can withstand large axial and radial forces. The design and material selection of the guide rail enable it to stably support the weight of moving parts while resisting various external forces generated during equipment operation. For a screw, its load capacity is determined by factors such as diameter, thread profile, and material strength. In large machine tools, guide screws need to withstand the weight of workbenches and workpieces weighing several tons, while also ensuring stable driving of the worktable for precise feed motion during high-speed cutting. This places extremely high demands on the load capacity of guide screws.

高传动效率

High transmission efficiency

滚珠丝杠的滚动摩擦方式相较于传统的滑动丝杠,大大提高了传动效率。由于滚珠与丝杠和螺母之间的滚动摩擦系数极小,使得电机的输出功率能够更有效地转化为直线运动的机械能。一般来说,滚珠丝杠的传动效率可以达到 90% 以上,而滑动丝杠的传动效率通常只有 20% - 50%。高传动效率不仅可以降低电机的能耗,节约能源,还能够提高设备的响应速度和运行速度。在自动化生产线中,快速的物料搬运和加工操作需要导轨丝杠具备高传动效率,以满足生产线上对高速、运行的需求。

The rolling friction method of ball screws greatly improves transmission efficiency compared to traditional sliding screws. Due to the extremely low rolling friction coefficient between the ball, screw, and nut, the output power of the motor can be more effectively converted into mechanical energy for linear motion. Generally speaking, the transmission efficiency of ball screws can reach over 90%, while the transmission efficiency of sliding screws is usually only 20% -50%. High transmission efficiency can not only reduce the energy consumption of the motor, save energy, but also improve the response speed and operating speed of the equipment. In automated production lines, rapid material handling and processing operations require guide screws with high transmission efficiency to meet the demand for high-speed and efficient operation on the production line.

本文由导轨丝杠向大家友情奉献.更多有关的知识请点击:http://www.jngongrun.com我们将倾情为您解答.

This article is dedicated to friendship by the guide screw For more related knowledge, please click: We will wholeheartedly answer your questions

- 上一篇:导轨丝杠是工业传动先锋的多维演进

- 下一篇:导轨丝杠的结构有哪些?

丝杠和轨杠哪个好用<>

丝杠和轨杠哪个好用<> 导轨丝杠故障诊断的新...<>

导轨丝杠故障诊断的新...<> 导轨丝杠的类型特点:...<>

导轨丝杠的类型特点:...<> 导轨丝杠的结构有哪些...<>

导轨丝杠的结构有哪些...<> 导轨丝杠的工作机制、...<>

导轨丝杠的工作机制、...<>